Choosing the Right Materials and Design

The foundation of a sturdy and beautiful rocking chair lies in selecting the right materials and designing its structure for optimal comfort and stability. This involves choosing the right wood, understanding the key design elements that contribute to a smooth rocking motion, and considering different styles that cater to individual preferences.

Wood Selection for Rocking Chair Construction

The choice of wood plays a crucial role in determining the durability, aesthetic appeal, and overall character of a rocking chair. Different wood types possess unique characteristics that influence their suitability for rocking chair construction.

- Oak: Known for its strength, durability, and beautiful grain patterns, oak is a popular choice for rocking chair construction. It is resistant to wear and tear, making it suitable for high-traffic areas. Oak’s natural resistance to moisture and insects also contributes to its longevity.

- Maple: Another hard and durable wood, maple is prized for its smooth, fine grain and warm color. It is a good choice for rocking chairs that require a delicate finish. Maple’s strength and resilience make it suitable for both traditional and contemporary designs.

- Cherry: Renowned for its rich, reddish-brown color and attractive grain patterns, cherry is a luxurious choice for rocking chairs. It is a relatively hard wood, but it can be susceptible to scratches and dents. However, its beauty and elegance make it a popular choice for heirloom rocking chairs.

- Pine: A softer wood, pine is known for its affordability and light, airy feel. It is often used for rocking chairs that are intended for casual use. Pine’s softness makes it easier to work with, but it is less durable than harder woods. It is also susceptible to scratches and dents.

Design Elements for a Comfortable and Stable Rocking Motion

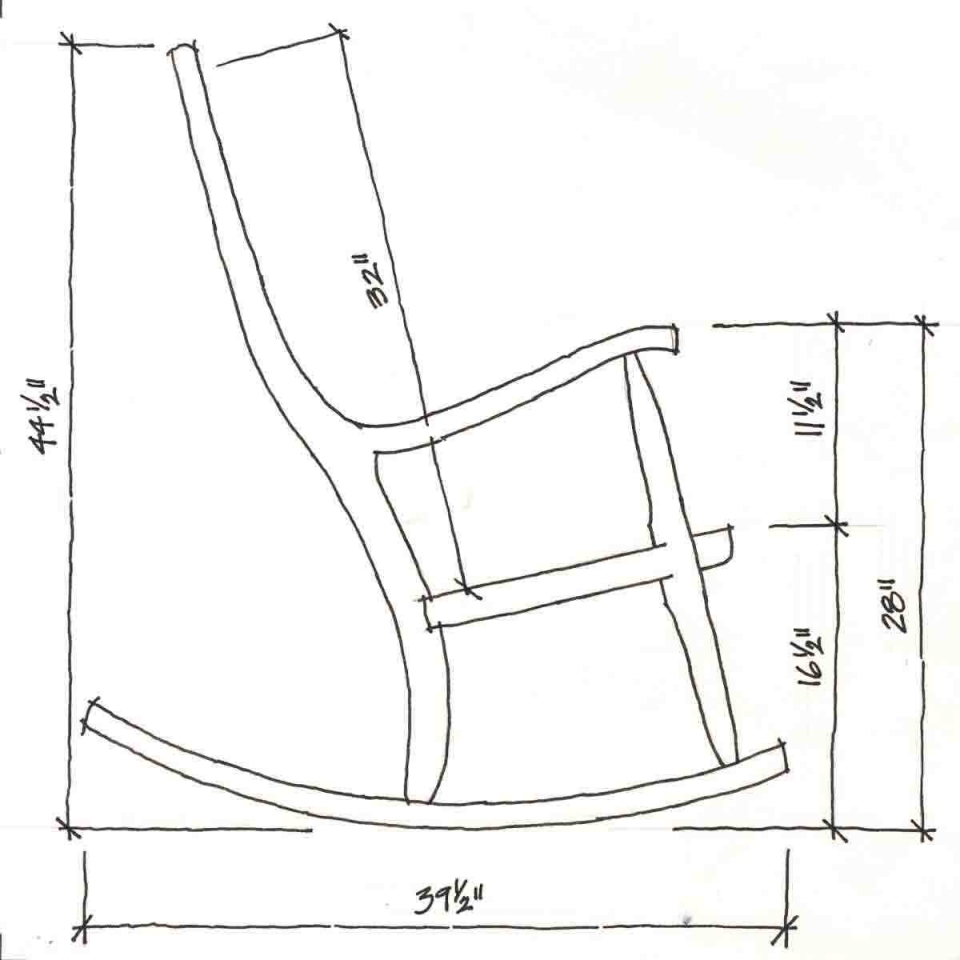

The shape and proportions of a rocking chair’s seat, backrest, and rockers play a crucial role in its comfort and stability. These elements work together to create a smooth and relaxing rocking motion.

- Seat Shape: A comfortable rocking chair seat should provide adequate support and contour to the body’s shape. The seat’s depth, width, and angle should be carefully considered to ensure a comfortable sitting experience. A slightly curved seat provides a gentle rocking motion, while a flat seat may feel less comfortable.

- Backrest Shape: The backrest should provide adequate lumbar support and be tall enough to support the upper back. The angle of the backrest can also influence the rocking motion. A steeper backrest will create a more vigorous rocking motion, while a shallower backrest will provide a gentler rocking experience.

- Rocker Shape: The shape of the rockers is crucial for a smooth and stable rocking motion. The curvature of the rockers should be gradual to ensure a gentle and consistent rocking motion. The width and length of the rockers also influence the rocking motion. Wider rockers provide a wider base and a more stable rocking experience, while narrower rockers create a more dynamic and lively rocking motion.

Classic Rocking Chair Styles

Throughout history, various rocking chair styles have emerged, each with its own distinctive features and appeal. These styles offer a diverse range of options for rocking chair enthusiasts.

- Windsor Rocking Chair: Characterized by its distinctive spindle-back design, the Windsor rocking chair is known for its sturdy construction and timeless elegance. The seat is typically made of a single piece of wood, and the spindles are often turned on a lathe. The rockers are typically curved and wide, providing a stable rocking motion.

- Adirondack Rocking Chair: Popular for its comfort and versatility, the Adirondack rocking chair features a wide, deep seat, a high backrest, and armrests. It is often made of cedar or pine and is designed to be weather-resistant. The rockers are typically curved and wide, providing a gentle rocking motion.

- Mission Rocking Chair: Inspired by the Arts and Crafts movement, the Mission rocking chair features clean lines, simple forms, and a focus on functionality. It is typically made of oak or maple and is characterized by its square or rectangular design elements. The rockers are typically curved and narrow, providing a smooth and elegant rocking motion.

Construction Techniques: How To Make A Rocking Chair

Building a rocking chair is a rewarding woodworking project that requires careful planning and precise execution. The construction process involves assembling the frame, creating the seat and backrest, and crafting the rockers. This section will delve into the specific techniques and steps involved in each stage.

Creating the Frame

The frame of a rocking chair serves as the foundation for the entire structure. It is typically made of sturdy hardwood, such as oak, maple, or cherry, which are known for their strength and durability.

The process of building the frame involves several steps:

* Cutting the Wood: The first step is to cut the wood pieces to the required lengths and angles. A table saw or miter saw is ideal for making accurate cuts. It is important to use a sharp blade and a steady hand to ensure clean and precise cuts.

* Shaping the Wood: Once the pieces are cut, they may need to be shaped to create curves or other desired forms. This can be done using a hand plane, a router, or a band saw. For intricate shapes, a band saw is often the best tool.

* Joining the Wood: The cut and shaped pieces are then joined together to form the frame. Various techniques can be used, including mortise and tenon joints, dovetail joints, or simple butt joints reinforced with glue and screws.

* Assembling the Frame: The frame is assembled using clamps and wood glue to hold the pieces in place while the glue dries. It is essential to ensure that the joints are tight and the frame is square before the glue sets.

Creating the Seat, Backrest, and Rockers

Once the frame is complete, the next step is to create the seat, backrest, and rockers.

Seat and Backrest

* Cutting and Shaping: The seat and backrest are typically made of plywood or solid wood. They are cut to the desired shape and size, then sanded smooth.

* Attaching to the Frame: The seat and backrest are attached to the frame using screws or dowels. It is important to ensure that the seat and backrest are securely fastened and aligned correctly.

Rockers

* Cutting and Shaping: The rockers are typically made of hardwood, such as oak or maple. They are cut to the desired length and curved shape. A band saw or a jigsaw is ideal for cutting the rockers.

* Attaching to the Frame: The rockers are attached to the bottom of the frame using screws or dowels. It is crucial to ensure that the rockers are securely fastened and that they are positioned symmetrically.

Essential Tools and Materials

Building a rocking chair requires a variety of tools and materials. Here is a list of essential items:

* Woodworking Tools:

* Table saw or miter saw

* Hand plane

* Router

* Band saw

* Jigsaw

* Drill

* Clamps

* Sandpaper

* Measuring tape

* Level

* Woodworking chisels

* Materials:

* Hardwood lumber (oak, maple, cherry, etc.)

* Plywood

* Wood glue

* Screws

* Dowels

* Wood finish (stain, paint, varnish)

Finishing Touches

After you’ve built your rocking chair, it’s time to give it that final touch of elegance and protection. This step involves sanding, staining, and applying a protective finish.

Sanding

Sanding is crucial for achieving a smooth and even surface. Start with coarse-grit sandpaper (80-120 grit) to remove any rough edges or imperfections. Gradually progress to finer grits (150-220 grit) for a smoother finish.

Staining, How to make a rocking chair

Staining adds color and depth to the wood, enhancing its natural beauty. There are various types of stains available, including oil-based, water-based, and gel stains.

Choosing the Right Stain

- Oil-based stains penetrate deeply into the wood, providing rich color and a natural look. They are durable but can take longer to dry.

- Water-based stains are easier to apply and clean up, but they don’t penetrate as deeply as oil-based stains. They are also less likely to raise the grain.

- Gel stains are thicker than oil-based or water-based stains, making them ideal for filling in pores and creating a more even finish. They also tend to be less messy.

Applying a Protective Finish

A protective finish seals the wood, protecting it from moisture, scratches, and UV damage. Popular choices include polyurethane, varnish, and wax.

Choosing the Right Finish

- Polyurethane is a durable and water-resistant finish that comes in both oil-based and water-based options. It provides a high-gloss or satin finish.

- Varnish is a thin, transparent finish that enhances the natural beauty of the wood. It is available in various gloss levels, from matte to high-gloss.

- Wax is a natural finish that provides a soft sheen and protects the wood from moisture and scratches. It is easy to apply and maintain.

Comparison of Wood Finishes

| Finish | Advantages | Disadvantages |

|---|---|---|

| Polyurethane | Durable, water-resistant, available in various finishes | Can be difficult to apply evenly, may yellow over time |

| Varnish | Enhances the natural beauty of the wood, available in various gloss levels | Less durable than polyurethane, can be more susceptible to scratches |

| Wax | Natural, easy to apply and maintain, provides a soft sheen | Less durable than polyurethane or varnish, requires regular reapplication |

How to make a rocking chair – While building a rocking chair requires woodworking skills and patience, for instant relaxation, consider the ootori nova n900 massage chair. This chair offers a luxurious massage experience, providing soothing comfort without the need for construction. Whether you prefer a gentle rocking motion or a targeted massage, the ootori nova n900 is a great alternative for those seeking immediate relaxation.

Building a rocking chair requires patience and skill, but the final product is well worth the effort. While you’re working on your chair, you might want to take a break and relax in an ijoy 300 massage chair for a soothing massage.

Once your rocking chair is complete, you’ll have a comfortable place to enjoy your woodworking masterpiece.